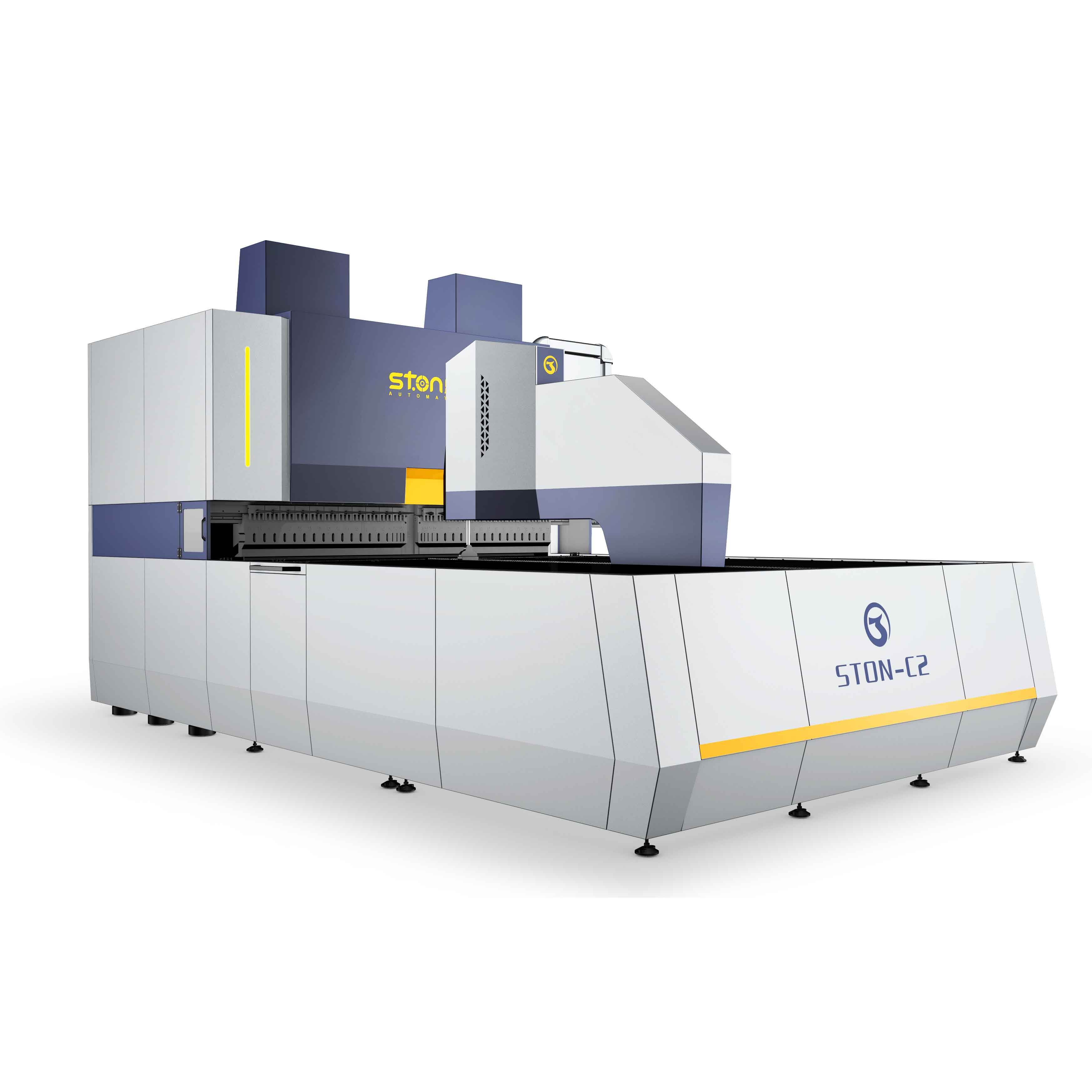

STON specialized in cnc machine manufacturing, including auto panel bender, cnc press brake, cnc turret punch press, automatic production line, etc.

STON specialized in cnc machine manufacturing, including auto panel bender, cnc press brake, cnc turret punch press, automatic production line, etc.

Our products are widely used in sheet metal processing, decoration, metallurgy, ships, automobiles, machinery, aviation and other professional production fields. Product quality is stable, continuous growth.

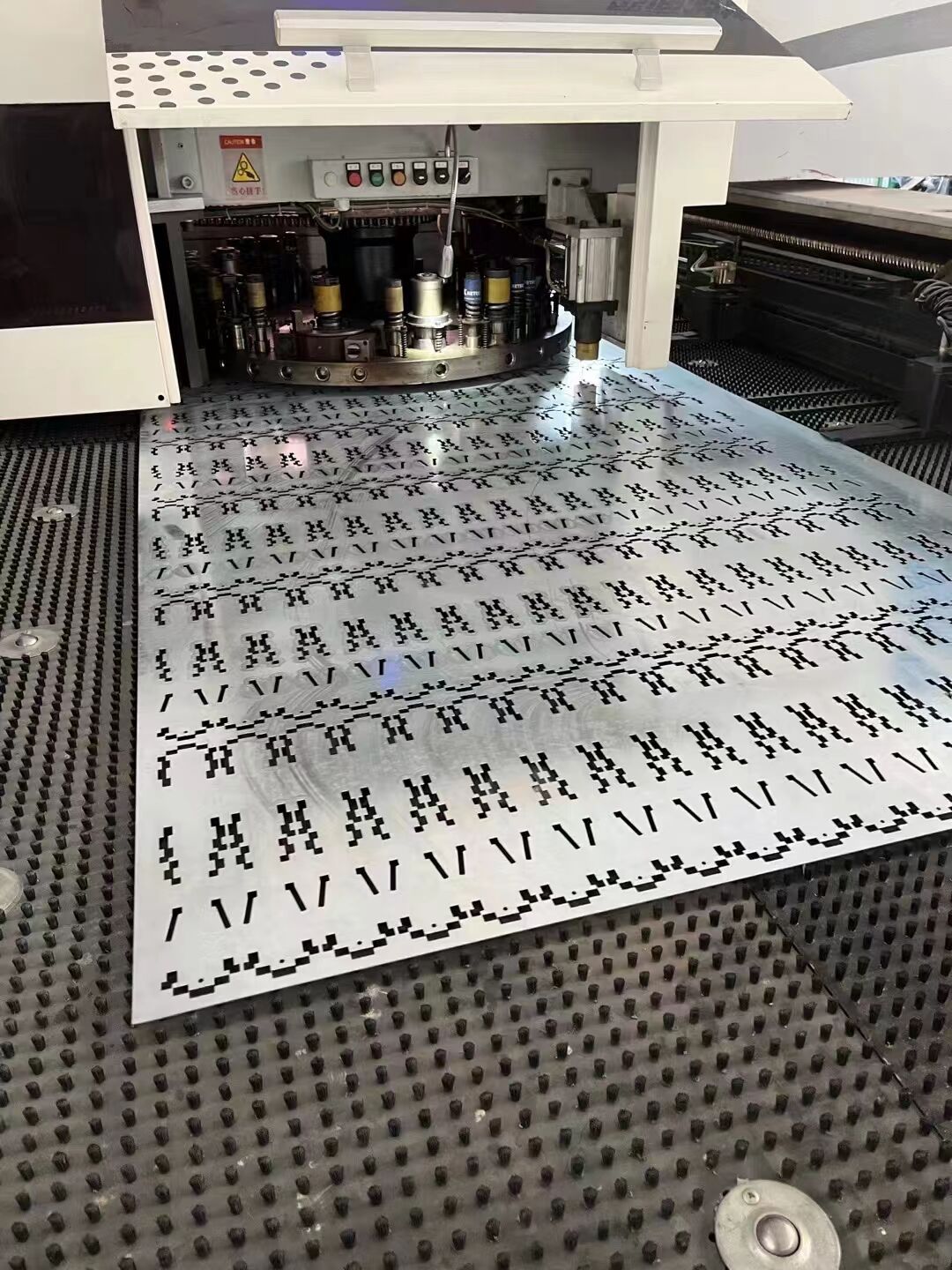

STON CNC turret punching machine is an advanced metal sheet processing equipment widely used in various industries such as electronics, electrical appliances, hardware, and automobiles. Working principle: The CNC turret punch press precisely controls...

The application of intelligent flexible bending center in the processing of inner panel sheet metal of shipping containers has the following significant advantages: 1. High precision bending: It can achieve bending accuracy up to the micrometer leve...

Large industrial air conditioning customer customization, bending length 3. 2m, sheet material for cold plate, bending thickness 2. 0mm, with the help of STON bending center, for customer enterprises to reduce costs and increase efficiency has made a...

The frame adopts an “O” shaped (closed) structure and is welded with steel plates. The steel plates have undergone strict material analysis to ensure the quality. It is designed according to the scientific movement mechanics. The main board and internal stiffeners are reasonably designed to ensure the overall stability of the frame.

The turbine worm reducer and double-chain drive are used to drive the cutter head. The reducer is installed inside the frame to enhance the transmission stability and displacement accuracy. The cutter head is designed with an enlarged cylinder seat and two cylinders, which has can run synchronously and position stably and accurately to avoid the wear of the side sleeve of the cutter head.

High-power hollow shaft servo motor is used to output power and the crankshaft is connected to the servo motor as a whole to avoid the misalignment and delay caused by too many connections. The direct-drive punching operation is featured by high stability and fast response speed, and the swing method is adopted. The swing angle is automatically selected according to the punching stroke and process to greatly improve the efficiency.

The Y-axis is designed with a one-piece connecting plate and the X-axis square tube beam is designed with two guide rails. After tempering treatment, the self-weight of the components is reduced, the operation is more stable and the positioning is more accurate. The guide rails and lead screws are imported from Taiwan and they are assembled according to strict and scientific assembly process. The company is also equipped with advanced laser collimator and laser interferometer to ensure assembly accuracy and effectively improve feeding accuracy and operating speed.

Qingdao Shengtong Mechanical Technology Co., Ltd., located in Qingdao West Coast , is adjacent to the Shenhai Expressway and Qingdao West Railway Station to the west and Qingdao International Airport at the back. The traffic is very convenient.

Cooperate with us

Qingdao Shengtong Mechanical Technology Co., Ltd., located in Qingdao West Coast , is adjacent to the Shenhai Expressway and Qingdao West Railway Station to the west and Qingdao International Airport at the back. The traffic is very convenient.

Rebecca

Qingdao Shengtong Mechanical Technology Co., Ltd., located in Qingdao West Coast , is adjacent to the Shenhai Expressway and Qingdao West Railway Station to the west and Qingdao International Airport at the back. The traffic is very convenient.

Eastyam

Our full-time after-sales service team is affiliated to the Sales Department and it can make timely response to the service requests.

In order to perform service work in a timely manner, our service team and common accessories are managed according to zones.

A number of technical service hotlines are provided to ensure rapid accessibility and timeliness.Handle user problems in a timely manner.