STON CNC turret punching machine is an advanced metal sheet processing equipment widely used in various industries such as electronics, electrical appliances, hardware, and automobiles. Working principle: The CNC turret punch press precisely controls...

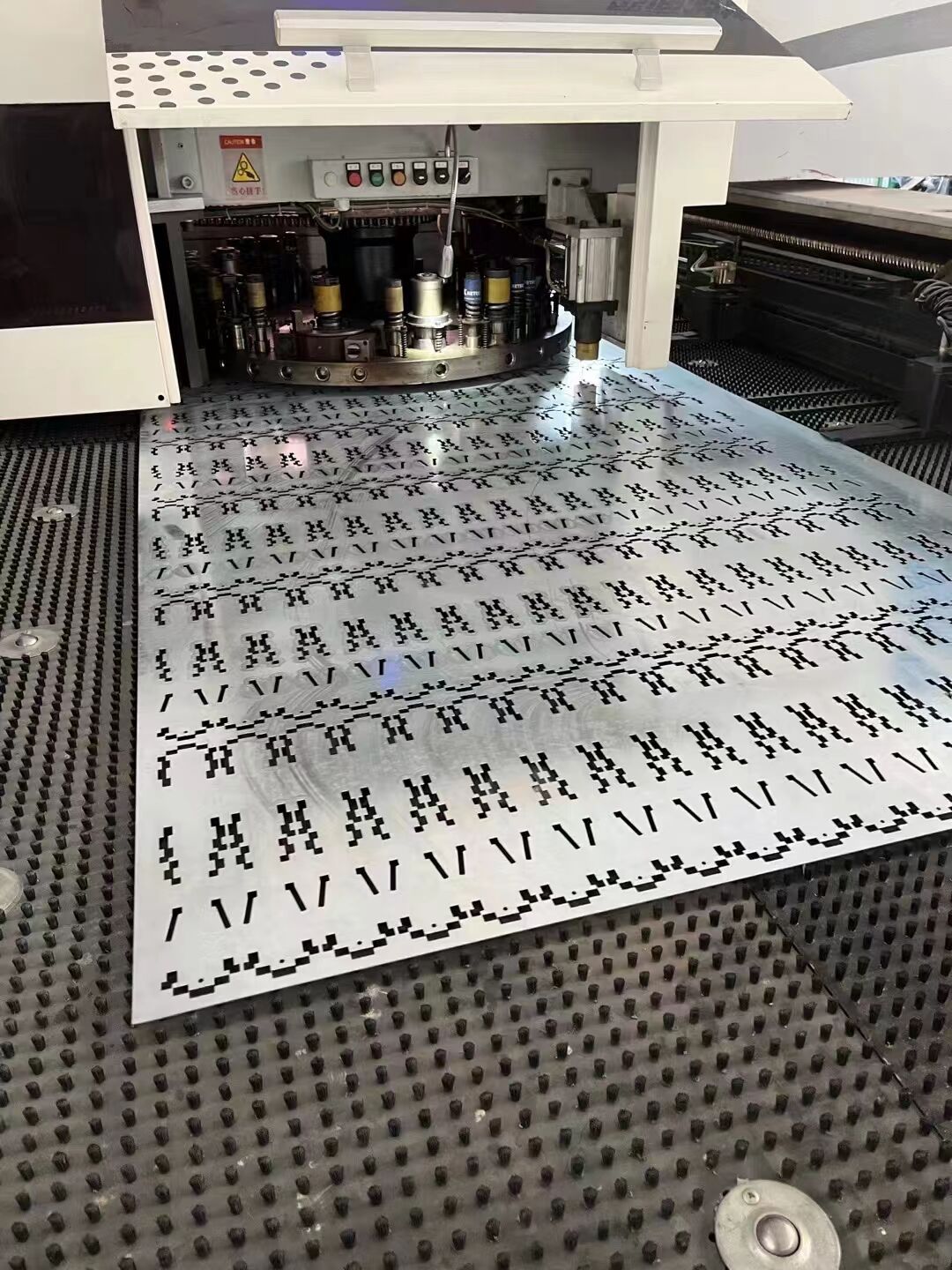

STON CNC turret punching machine is an advanced metal sheet processing equipment widely used in various industries such as electronics, electrical appliances, hardware, and automobiles.

Working principle:

The CNC turret punch press precisely controls the movement and cutting action of the punch through a computer numerical control (CNC) system. The board is fixed on the workbench, and multiple molds of different shapes and sizes are installed on the turret. According to the pre programmed machining program, the punch moves in the X and Y axis directions, and suitable molds are selected for processing operations such as punching, cutting, stretching, and forming.

Process characteristics:

1. High precision: capable of achieving machining accuracy up to the micrometer level, ensuring the accuracy of punching hole positions and shapes.

2. High efficiency: The automated processing process quickly completes a large number of punching and cutting tasks, greatly improving production efficiency.

3. Multifunctional: It can complete various processes such as punching, corner cutting, shallow stretching, and embossing, meeting the processing needs of complex parts.

4. Flexibility: By replacing the mold on the turret, it can quickly adapt to different shapes and sizes of punching requirements, achieving small batch and multi variety production.

5. Convenient programming: Use professional CAD/CAM software for programming, with simple operation and easy modification and optimization of machining programs.

Processing process:

1. Plate preparation: Cut the metal plate to be processed to the appropriate size and clean the surface of oil and impurities.

2. Clamping positioning: Fix the sheet metal on the punching machine workbench to ensure its accurate and stable position.

3. Programming design: Based on the part drawings, use CAD/CAM software to generate machining programs, including punch motion trajectory, mold selection, punching sequence, etc.

4. Machine tool debugging: Before formal processing, perform idle operation and trial punching to check the correctness of the program and the working status of the machine tool.

5. Batch processing: After debugging without errors, start the machine tool for batch processing.

6. Quality inspection: Inspect the size, shape, surface quality, and other aspects of the processed parts to ensure compliance with requirements.

Application field:

1. Electronics industry: Used for processing panels, chassis casings, etc. Of various electrical control cabinets.

2. Hardware products: manufacturing components for metal furniture, kitchenware, locks, etc.

3. Automobile manufacturing: producing automotive body panels, interior parts, etc.

The CNC turret punching machine technology, with its high precision, high efficiency, and multifunctional characteristics, provides efficient and flexible metal sheet processing solutions for modern manufacturing industry.