1.Fully Electrical Servo System

2.Smart Energy Consumption System

3.Operator-independent Production

4.High Repeatability Precision

5.Ergonomic and Safe Working Area

6.Low Maintenance Cost

7.Low Tool Cost

8.Easy and Fast Installation

| STZ03-A2 | STZ03-B1 | STZ03-B1 | STZ03-B2 | STZ03-C2 | STZ03-D2 | STZ03-E2 | |

| Max. bending speed | 0.2s | 0.2s | 0.2s | 0.2s | 0.2s | 0.2s | 0.2s |

| Max. bending length (CM) | 100*100 | 140*125 | 140*125 | 160*125 | 200*150 | 250*150 | 320*150 |

| Max. bending height (mm) | 170/210 | 170/300 | 170/300 | 170/300 | 170/300 | 170/300 | 170/210 |

| Feeding method | Press arm type | Suction cup type | Press arm type | Press arm type | Press arm type | Press arm type | Press arm type |

| Feeding table | Brush, universal ball | Brush, universal ball | Brush, universal ball | Brush, universal ball | Brush, universal ball | Brush, universal ball | Brush, universal ball |

| Lubrication pipeline | Copper pipe | Copper pipe | Copper pipe | Copper pipe | Copper pipe | Copper pipe | Copper pipe |

| Min. bending thickness (mm) | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 |

| Min. four-sided forming size | 200*280mm | 200*280mm | 200*280mm | 200*280mm | 200*280mm | 200*280mm | 200*280mm |

| Single-sided forming | 150mm | 150mm | 150mm | 150mm | 150mm | 150mm | 150mm |

| Hinge knife | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| Advanced command | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| Arc command | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| Replacement of suction cup assembly width | Standard | ||||||

| Suction cup group lifting | Optional | ||||||

| Press foot lifting | Optional | Optional | Optional | Optional | Optional | Optional | Optional |

| C-axis lifting | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| Automatic lubrication function | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| Bias load detection function | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| Bias load follow-up function | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| Plate thickness detection function | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| Automatic feeding interface | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| High speed control module | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| Flattening function | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| up/down pressed dead edge | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| Knife adjustment device | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| hand wheel | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| Cloud-based management function | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| Rated voltage | 380V | 380V | 380V | 380V | 380V | 380V | 380V |

| Max.bending.thickness (mm) | Stainless steel 1.0 Cold plate 1.2 Aluminum plate 1.5 | Stainless steel 1.2 Cold plate 2.0 Aluminum plate 2.5 | Stainless steel 1.2 Cold plate 2.0 Aluminum plate 2.5 | Stainless steel 1.2 Cold plate 2.0 Aluminum plate 2.5 | Stainless steel 1.2 Cold plate 2.0 Aluminum plate 2.5 | Stainless steel 1.2 Cold plate 2.0 Aluminum plate 2.5 | Stainless steel 1.2 Cold plate 2.0 Aluminum plate 2.5 |

| Dimensions (CM) | L* W *H 310 * 150 * 280 | L* W *H 350 * 200 * 280 | L* W *H 450 * 200 * 280 | L* W *H 450 * 250 * 280 | L* W *H 510 * 270 * 280 | L* W *H 570 * 310 * 280 | L* W *H 700 * 380 * 280 |

|

No. |

Name |

Supplier/Brand |

|

1 |

Control system |

Xindai Taiwan / Trio UK |

|

2 |

Servo motor, drive |

Xindai Taiwan / Trio UK |

|

3 |

Cast body |

Xuchang, Henan |

|

4 |

Welded body |

Qingdao STON |

|

5 |

Feeding rack |

Qingdao STON |

|

6 |

Reducer |

Taiwan Dingrui/ROUIST |

|

7 |

Screw rod |

Nanjing Technical Equipment/Shaanxi Hanjiang |

|

8 |

Guide rail |

Nanjing Technical Equipment/ROUIST |

|

9 |

Bearing |

Japan NSK/NACHI |

|

10 |

Negative pressure pump |

Zhejiang Tengyuan (Press arm type excluded) |

|

11 |

Electrical parts |

Schneider, Omron |

|

12 |

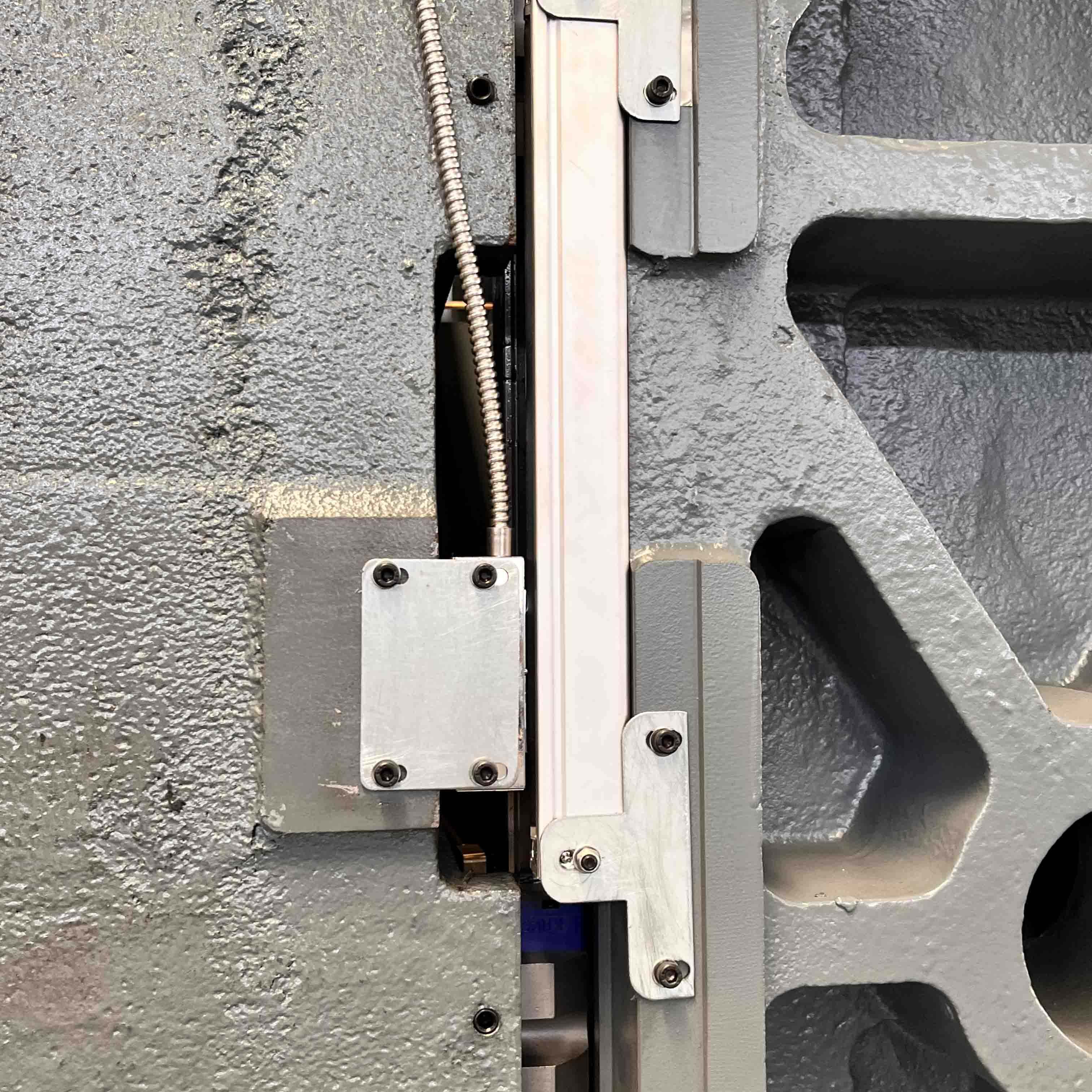

Grating ruler |

Suzhou SINO |

|

13 |

hand wheel |

Taiwan FUTURE |

|

14 |

Machine air conditioning |

Tongfei Refrigeration |

|

15 |

Pneumatic accessories |

Taiwan AirTAC |

|

16 |

Suction cup |

AIRBEST (Press arm type excluded) |

|

17 |

Coupling |

Miki Pulley |

|

18 |

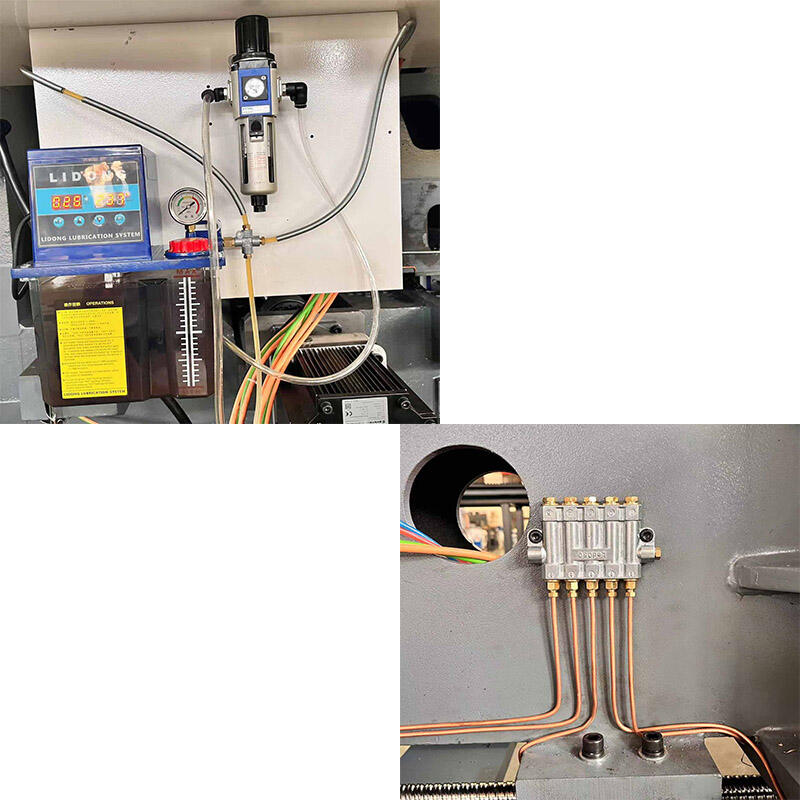

Lubrication system |

Guangdong Dingshen |

| CASTING MACHINE BODY |  |

The main body parts of the machine are casting parts instead of welding parts which are commonly used in the market. The casting parts undergo open-air aging treatment after rough machining to completely release the internal stress before fine machining to ensure that they can be used for a long time without deformation and ensure the stability of overall accuracy. High-grade welding body parts is also optional according to customer's requirements. |

| ROUGH PROCESSING /FINE PROCESSING |  |

Instead of doing rough and fine processing by outsourcing suppliers, for all parts, we do both rough machining and fine machining according to strict characteristics rules in our own workshop. Such as high-temperature annealing treatment, shot blasting,open-air internal stress release, and fine processing by large CNC floor boring machine and CNC drilling and milling machine and machining center, so that ensure they can be used for a long time without deformation and ensure the stability of overall accuracy. |

| GUIDE RAIL SCREW ROD AND BEARINGS |  |

Large diameter grinding grade screw rods are used according to the operation requirements of different types of equipment. NSK/NACHI bearings imported from Japan are used together to have higher load capacity and transmission accuracy. Wide roller guide slider has excellent anti-wear performance and strong load bearing performance. It can effectively improve the operation stability and prolong service life of equipment. |

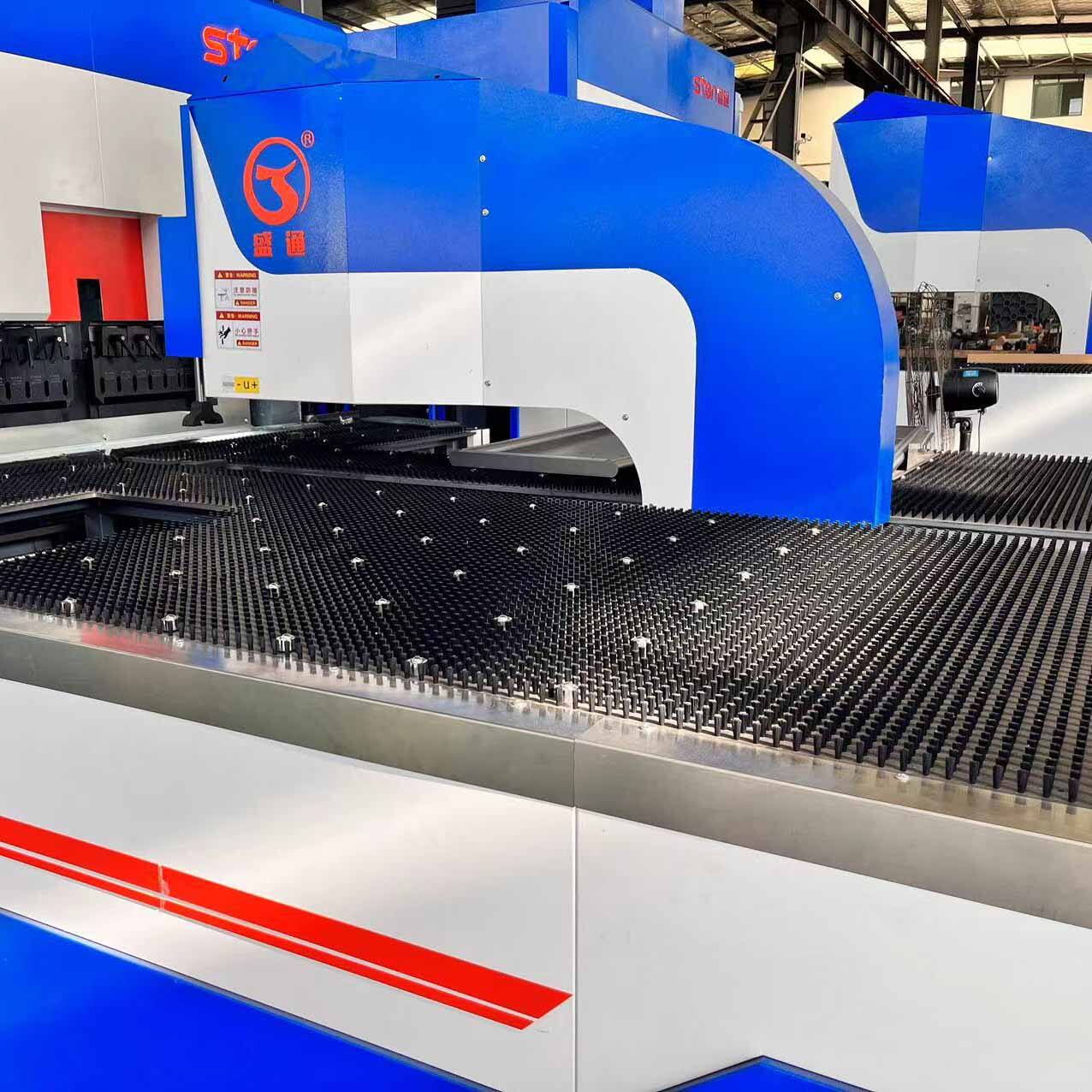

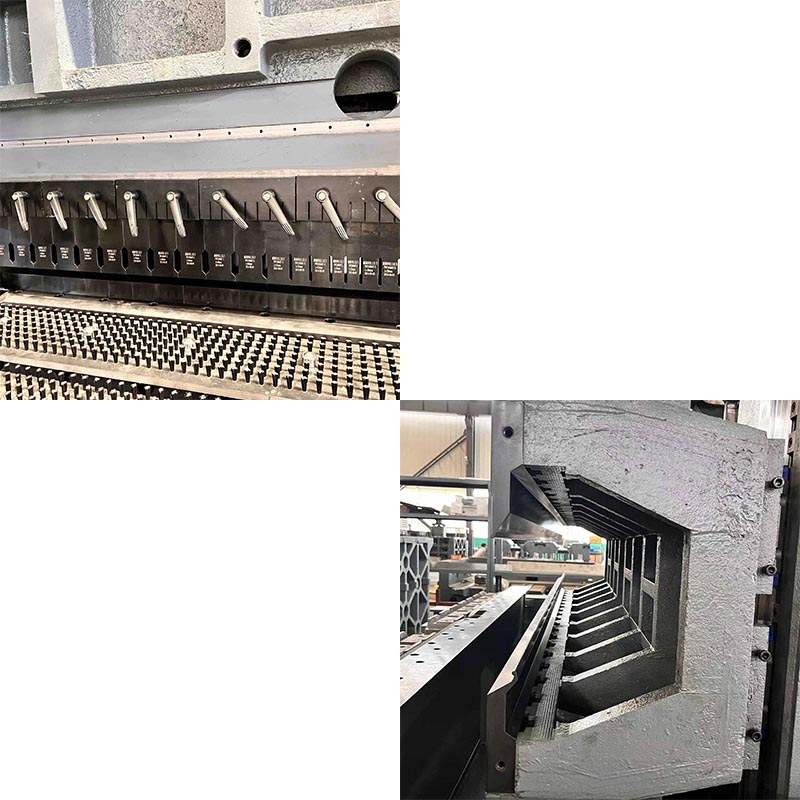

| FEEDING RACK |  |

The feeding rack is welded with thick-walled pipes and annealed by electric furnace at high temperature for high stability. Then machined by large floor boring machine to ensure the fitting precision with the mounting surface of the body. The surface adopts the combination of brush and universal ball to protect the plate from being scratched and increase the rotation speed. |

| UPPER/LOWER PRESS KNIVES AND BENDING KNIVES |  |

Made of 42CrMo forging material and it undergoes strict rough and fine machining, heat treatment, tempering and laser quenching to ensure the service life of the tool and bending requirements. |

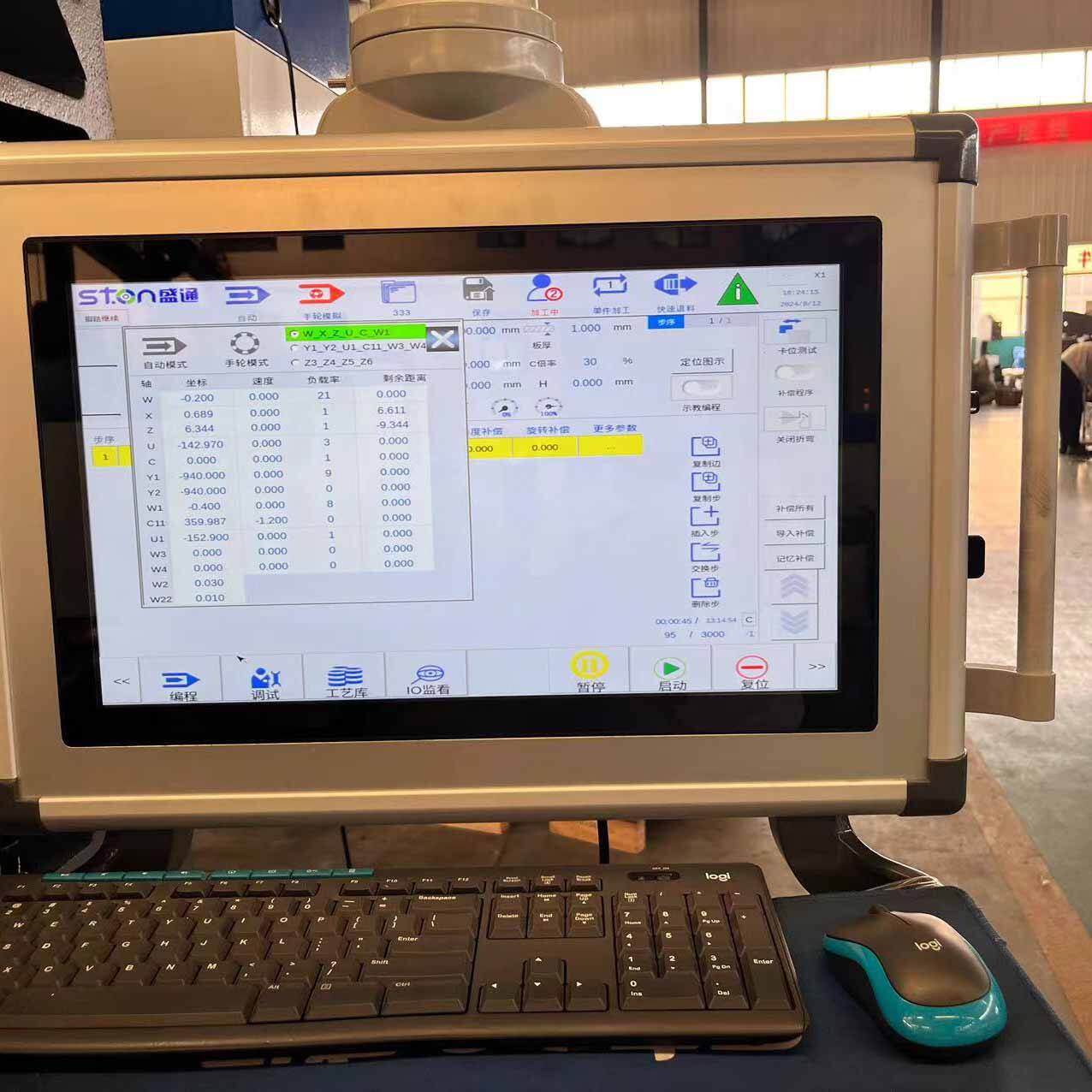

| CONTROL SYSTEM |  |

Adopted imported all-electric servo closed-loop control system, which supports simultaneous linkage of up to 25 axes to truly achieve multi-axis simultaneous linkage, smooth bending action and high coordination of mechanical operation. The connecting ports are reserved for the control system for truss loading/unloading equipment and manipulator, so that users can connect different brands of manipulators and truss loading/unloading equipment according to their needs. |

| SERVO MOTORS |  |

Choose imported/domestic servo motors according to actual bending torque and different user needs. Servo motor signal is transmitted via bus and the control system is used to achieve closed-loop control. It ensures the real-time detection of signal transmission to avoid the signal loss and non-detectable transmission of signals |

| HAND WHEEL |  |

This design makes it more convenient to adjust the knive position and accuracy test. Avoid damage to tools and equipment caused by misoperation during system control, and reduce the waste in the process of bending test. |

| ELECTRIC COMPONENTS |  |

Adopt imported electrical equipment to ensure the stability of the control system; The electrical cabinet is equipped with domestic famous brand air conditioner to dissipate heat in the electrical cabinet |

| UNIQUE DISTURBANCE COMPENSATION DESIGN |  |

The unique disturbance compensation design is used to solve the bending angle and straightness compensation problems of different lengths, different plate thicknesses and different materials so as to effectively control the angle and straightness tolerance of the workpiece within the minimum range. |

| GRATING RULER DETECTION |  |

Bias load detection system, effectively protect the machine/workpiece and reduce the waste of the workpiece |

| LUBRACATION SYSTEM |  |

Automatic lubrication system ensures the moving parts are lubricated in time, prevent the wear of screw rod balls and guide roller caused by the lack of oil and lubrication, and prolong the service life of the screw rod and guide rail. Compared with plastic pipelines commonly used by other suppliers, our equipment uses copper lubrication pipeline to eliminate the aging and bursting of plastic pipeline. |

| ELECTRIC HINGE(OPTIONAL) |  |

Compared with gravity hinge knives which are commonly used by other companies, Shengtong machines adopt electric control hinge knives, which can greatly reduce the demage to workpieces when the hinge knives touch and leave the workpieces. |

| AUXILIARY KNIVES(OPTIONAL) |  |

Auxiliary knives can be added for complex bending processes to meet various bending requirements |

| C AXIS UP/DOWN(OPTIONAL) |  |

For cases that workpieces need down folding, C axis can company with U1 axis to lift the workpieces, effectively prevent the workpieces from being destroyed when withdrawing. |

STON intelligent panel bender can be widely used in the the field of all kinds of cabinets, such as file cabinet, tool cabinet, outer guard cover, electrical cabinet, communication cabinet, gas cabinet, water meter cabinet and so on ), kitchenware(refrigerator,air conditioning, stove ).furniture, ventilation, refrigeration, purification, metal door industry, decoration, elevators and other related metal forming fields.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|