Jämfört med traditionella tryckbågar levererar CNC-tryckbågar bättre böjdningsnoggrannhet och effektivitet, vilket möjliggör en 30% ökning i böjningstider inom samma tidsperiod.

Modell:PBS/PBE 1500mm-4100mm

Kontrollmärke: DELEM, CYBELEC, ESA

Förmåga: 30T - 5000T

| Maskinmodell | böjkraft (KN) |

Böjbar bredd (mm) |

Kolumnavstånd (mm) |

Öppen höjd (mm) |

Trottojdjup (mm) |

Cylinderväg (mm) |

vertikal platta | sidopanel | glidare | Huvudmotoreffekt (KW) |

Hydrauloljens vikt (L) |

hastighet (mm/s) | Ytterdimensioner (mm) | ||||

| tjocklekar (mm) | drivkraft | neutralisera | returresan | Dimensioner Längd | bredd | Höjd | |||||||||||

| PBS-63/1500 | 600 | 1500 | 1200 | 580 | 350 | 215 | 70 | 40 | 50 | 8.7 | 130 | 185 | 19 | 180 | 2000 | 1620 | 2470 |

| PBS-63/2100 | 600 | 2100 | 1600 | 580 | 350 | 215 | 70 | 40 | 50 | 8.7 | 170 | 185 | 19 | 180 | 2600 | 1620 | 2470 |

| PBS-63/2550 | 600 | 2550 | 2050 | 580 | 350 | 215 | 70 | 40 | 50 | 8.7 | 200 | 185 | 19 | 180 | 3150 | 1620 | 2500 |

| PBS-100/3200 | 1000 | 3200 | 2700 | 580 | 390 | 215 | 80 | 50 | 60 | 10.8 | 300 | 220 | 17 | 210 | 3720 | 1720 | 2550 |

| PBS-100/4100 | 1000 | 4100 | 3600 | 580 | 390 | 215 | 90 | 50 | 70 | 10.8 | 400 | 220 | 17 | 180 | 4620 | 1720 | 2550 |

| PBS-150/3200 | 1500 | 3200 | 2700 | 580 | 405 | 215 | 90 | 60 | 70 | 13.2 | 300 | 180 | 14 | 180 | 3780 | 1730 | 2600 |

| PBS-150/4100 | 1500 | 4100 | 3600 | 580 | 405 | 215 | 100 | 60 | 80 | 13.2 | 400 | 180 | 14 | 170 | 4680 | 1730 | 2600 |

| PBS-220/3200 | 2200 | 3200 | 2700 | 580 | 405 | 215 | 100 | 70 | 80 | 16.7 | 300 | 160 | 12 | 160 | 3830 | 1800 | 2670 |

| PBS-220/4100 | 2200 | 4100 | 3600 | 580 | 405 | 215 | 110 | 70 | 90 | 16.7 | 400 | 160 | 12 | 150 | 4730 | 1800 | 2670 |

Anmärkningar; N är antalet axlar, inklusive Y1, Y2, X, R och andra axlar; V är kompensationsaxeln (mekanisk kompensation)

Konfigurationslista för PBS100T CNC-maskin

|

Nej. |

Namn |

Modell |

Varumärke |

|

|

1 |

CNC SYSTEM |

DA53T |

DELEM, Nederländerna |

|

|

2 |

Servomotor för bakåtgeär |

EM3G-09 |

ESTUN |

|

|

3 |

Servostyrning för bakåtgeär |

ED3L-10AMA |

ESTUN |

|

|

4

|

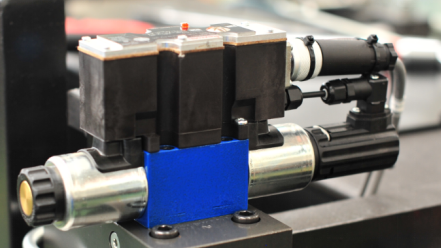

Hydraulsystem Huvudventiler

|

Elektro-hydraulisk servo-hydraulisk värdesten |

Bosch-Rexroth, Tyskland |

|

|

Synchroniseringsstyrningsmodul

|

a. Återtrycksväv |

|

||

|

b. Poppetväv |

|

|||

|

c. Proportionservoventiler |

|

|||

|

Hydraulstyrningsmodul

|

a. Kassettväv |

|||

|

b. Trycksensor |

|

|||

|

c. Riktningsspetsar |

|

|||

|

d. Proportionella tryckminskningsventiler |

|

|||

|

5 |

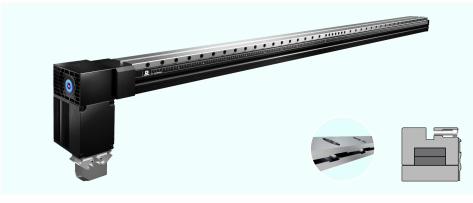

Linjeguidage

|

35 |

AIRTAC/SHAC |

|

|

25 |

AIRTAC/SHAC |

|||

|

6 |

Ballscrew |

880/1000 |

PMI/Tyskland VOLLEY |

|

|

7 |

Oljepumpen |

LXPG1H-20 |

Bosch-Rexroth, Tyskland |

|

|

8 |

Cylindersegel |

Set A fullständigt set med seglar |

PARKER eller SKF. |

|

|

9

|

Komplett uppsättning högtrycksledning

|

1.GE16 ZSR 3/4EDCF |

PARKER/BRENNAN (USA)

|

|

|

2.GE28 LR3/4EDOMDCF |

||||

|

3. W10 ZLCF |

||||

|

4. WH10 ZSR KDSCF |

||||

|

5. WH10 ZLR KDSCF etc. |

||||

|

10 |

Kopplingar |

GGRMP |

SIT |

|

|

11 |

AC-kontaktorer/knappar |

LC1D, XB2B, OSM |

Schneider |

|

|

12 |

Fotväxlar |

HRF-HD5NX |

Korea Kaikun |

|

|

13 |

Huvudservomotor |

EMB-1ZDDRC22(10.8KW) |

ESTUN |

|

|

14 |

Huvudservodriv |

PRONET-1ZDDRC |

ESTUN |

|

|

15 |

Magnetmåttskala |

MPS/GVS215LC |

OPKON, Turkiet |

|

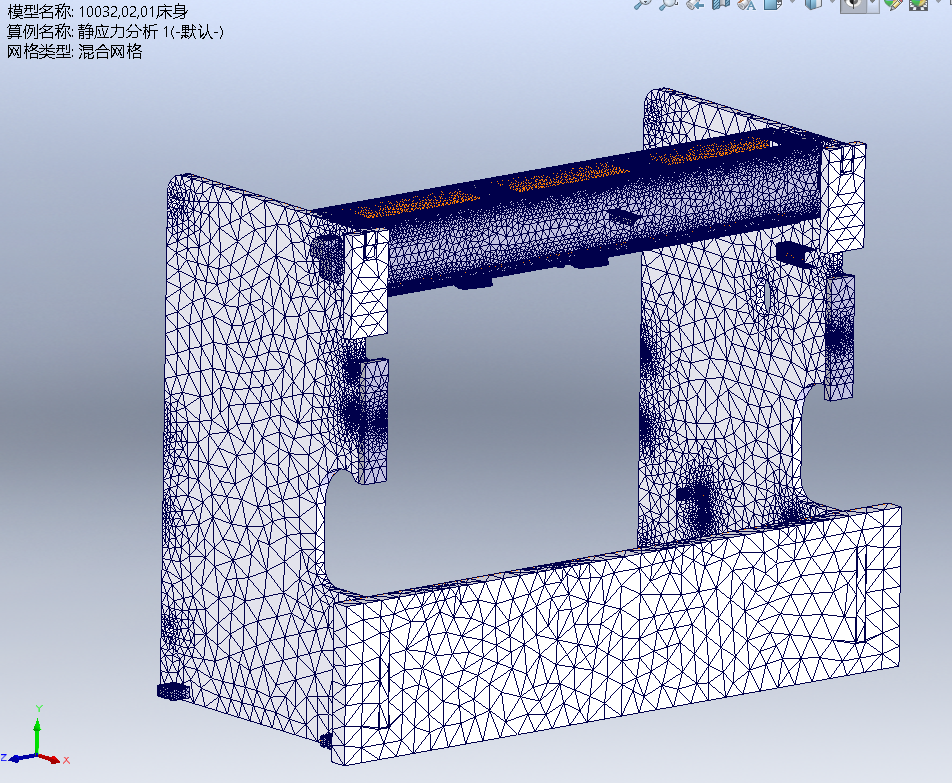

Maskinkroppen är utformad genom finita elementoptimering för att säkerställa att maskinen har hög styrka och styvhet när den används.

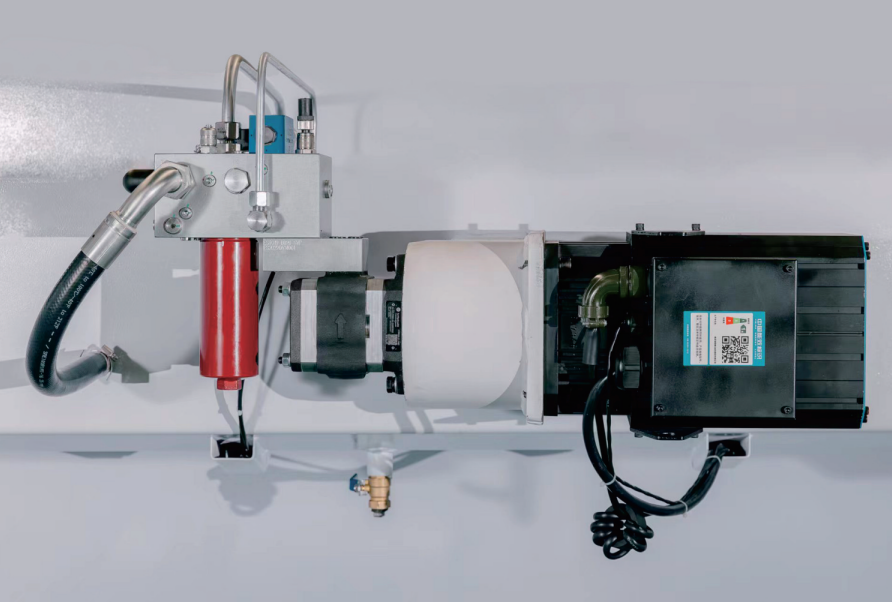

Jämfört med traditionella CNC-målingsmaskiner använder huvudmotorn en servomotor, med tillagd trycksensor, ökad motorhastighet, ökad vätskeflöde och pumpdisplacement, vilket gör att Y-axelns rörelse blir mjukare och mer effektiv. Blixt-effektiviteten har ökat med 30% jämfört med de främsta modellerna på marknaden;

Huvuddrift med servomotorer, Y-axelns hastighet i varje tillstånd skiljer sig, vilket minskar hydrauliskt överflöde avsevärt, därmed minskar energiförbrukning och oljtemperatur, vilket sparar 30-40%. På grund av den låga oljtemperaturen har hydrauloljens livslängd ökat betydligt;

Genom att använda det fullständigt stängda tyska Rexroth elektrohydrauliska servo-synkroniserade styrsystemet säkerställs att maskinen har hög stabilitet och precision under höghastighetsdrift.

Med mer rationell stängd höjd, strupdjup, inre blockavstånd och skivsträckning jämfört med de främsta böjmaskinerna förbättras prestandan, vilket gör det enklare att böja, ta upp stora och komplexa arbetsstycken utan att ytterligare kostnader krävs för att uppnå bättre resultat.

Hela stålplattan svetsas som en helhet, med starkt motstånd mot vibrationer.

Genom att använda vibrationsåldring elimineras interna spänningar i ramen, god stabilitet, raman är inte lätt att deformeras.

Ramen formges av en femsidig bearbetningscenter, vilket säkerställer parallellitet och vinkelrättighet mellan varje monteringsyta.

Strupen på ramen är utrustad med en ”C”-rammekanism, vilket garanterar böjnoggrannhet och stabilitet.

Oljcylindersegler, rörledningsfogar för PARKER/SKF eller BRENNAN från USA, starkt seglade, lång livslängd;

Använder det mest avancerade fullständigt stängda elektrohydrauliska servo-synkroniserade styrsystemet;

Maskinen kan arbeta kontinuerligt under den nominella belastningen, medan hydraulsystemet säkerställer ingen läckage och kontinuerlig stabil bearbetning med hög precision;

Hållsakets hastighet är snabb och positioneringsnoggrannheten är hög;

Axlarna X och R drivas av importerade bollscrewar, vägda av linjära ledningar och drivas av digitala AC servomotorer med stödfunktion;

Hållfingern rör sig vänster och höger längs linjära ledningen, med finjusteringsfunktion i frams- och bakriktning, enkel att använda och hög precision;

Använder unik hållstrukturen, med en nivå~tre nivåer hållfingersfunktion, utökar blockmaterialomsättningen;

Elektronikkomponenterna använder utländska eller joint venture-märken, vilka är i enlighet med internationella standarder, och el-kontrollskåpet är utrustat med en kylningss enhet;

Analogkabeln är sköldad för att eliminera elektrisk störning;

Tätningen av el-kontrollskåpet uppfyller nationell standard IP54 skyddsnivå;

Fotspakarna använder dubbla fotpedaler, som kan gå upp och ner, bekväma och enkla;

Mekanisk kompensationsarbetsbänksdesign med centralspill och plan installation av universell typ;

Använder strukturen för täta punktpositioner med skev vinkelkompensation för att uppfylla kraven på vinkelmässig noggrannhet vid böjning av hela arbetsstycket.

Standardutrustad med integrerad gearmotor, aluminiumskydd och skal;

Kompensationsstängd loopkontroll, hög kontrollnoggrannhet, kompensationsmängden beräknas och inställs automatiskt av CNC-systemet för att säkerställa konsekvensen i vinkelbøjningen över hela längden;

Nederländska DELEM-företagets DA53T numeriska styrsystem

1, 10.1” högupplöst färg-TFT-skärm;

2, Maximalt fjärde-axelskontroll (Y1, Y2, X, R-axel);

3, 266MHZ-processorn;

4, inbyggd lagringskapacitet 1 GB;

5, USB-lagringsgränssnitt, RS232-gränssnitt;

6, formbibliotek, 30 övre former, 30 nedre former;

7, inbyggd programmerbar PLC, stabil och pålitlig, logiken kan spara hårdvarans kopplingar;

8, ensidig parameter-snabbprogrammering, navigationsgenvägsknappar;

9, bordets böjningskompensation beräknas automatiskt;

10, standarddataprogrammering, grafisk programmering valfri, stöd för stora bågar, tryckbottenböjning;

11, nödstoppsväxelpanel;

12, automatisk beräkning av böjningstryck, form säkerhetszon;

13, online körsanalysverktyg;

14, vinkelkorrektionsdatabas;

15, systemdiagnostisk funktion;

16, Delem-Linux operativplattform för att säkerställa stabiliteten i systemets drift, stöd för omedelbar nedstängning;

17, standard offline programmeringsprogramvara;

18, valfri dubbelmaskinlänkfunktion;

19, diagnostikfunktioner, kan övervaka IO-digitalsignalerna, övervaka analoga signaler, statusen för varje axel;

20, automatisk summering av maskins arbets tid och böjningsantal;