STON intelligent flexible bending center application in new energy charging pile industry: 1. Improve production efficiency and batch consistency Quick response: The intelligent flexible bending center can quickly adjust and adapt to the production n...

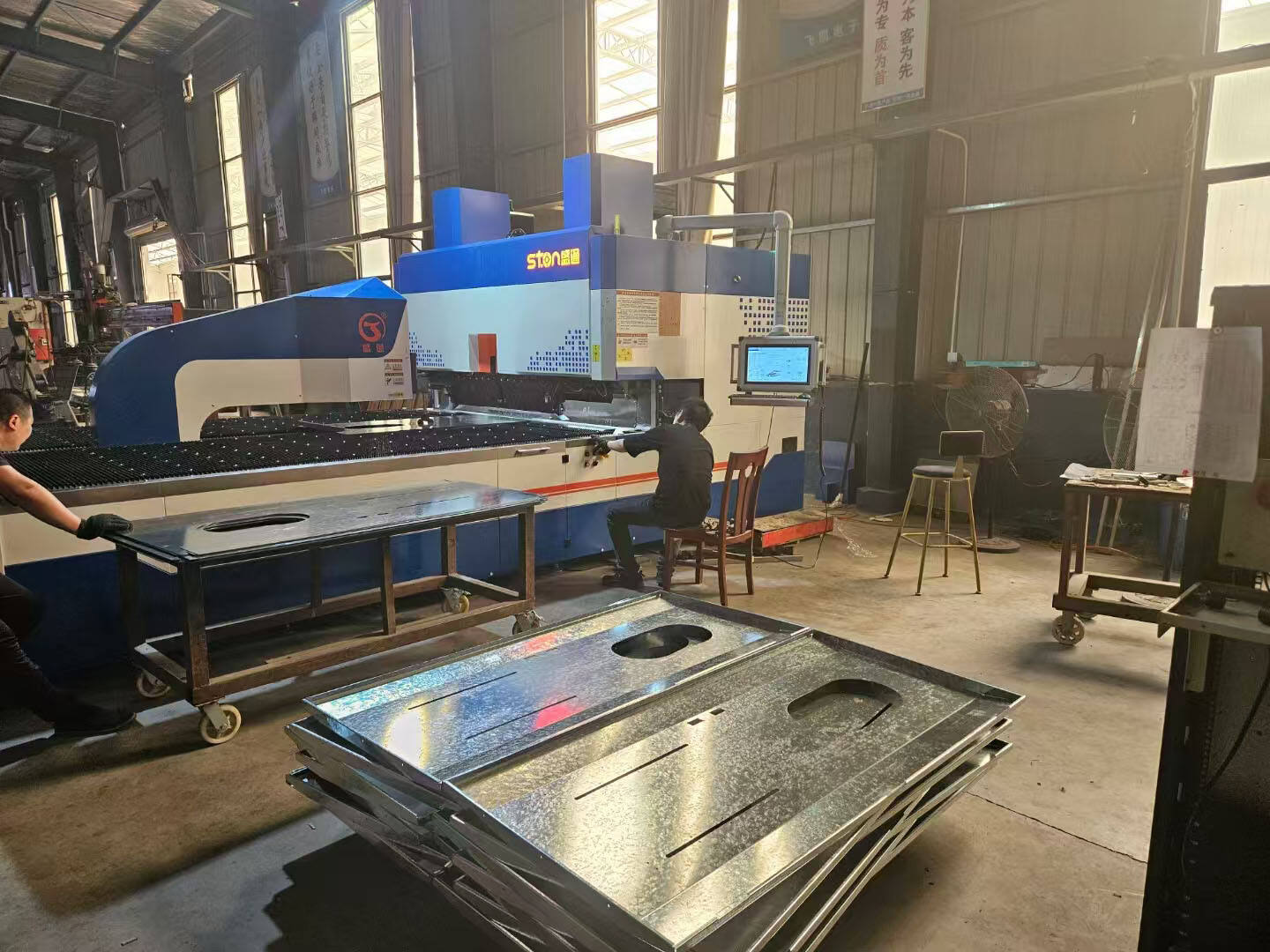

STON intelligent flexible bending center application in new energy charging pile industry:

1. Improve production efficiency and batch consistency

Quick response: The intelligent flexible bending center can quickly adjust and adapt to the production needs of different types of charging pile shells and components.

Reduce switching time: Automated adjustment and programming greatly reduce the time to switch between different models or specifications.

2.Improve the manufacturing accuracy of charging pile shells

High precision: The intelligent bending equipment provides high-precision bending and forming to ensure the consistent size and shape of the charging pile shell.

Consistency and reliability: Through advanced sensors and feedback control systems, the bending quality of each workpiece is guaranteed to be stable.

3. Adapt to the processing of different materials and realize diversified design needs

Multi-material compatibility: It can handle a variety of materials (such as stainless steel, aluminum alloy, etc.) to meet the needs of different charging pile shell designs.

Diversified design support: It can support complex designs and diverse charging pile appearance requirements, providing design and manufacturing flexibility.

4. Reduce production costs

Reduce material waste: High-precision bending and forming reduce material waste, thereby reducing production costs.

Optimize human resources: The improvement of automation level reduces dependence on manual labor, thereby reducing labor costs.

5. Enhance the visualization and management of production lines

Real-time monitoring: Through the Internet of Things and cloud computing technology, real-time monitoring and data collection of the production process are realized.

Predictive maintenance: Use big data analysis and machine learning to predict equipment failures and reduce unplanned downtime.

6. Environmental benefits

Reduced energy consumption: The optimized design and advanced technology of the intelligent bending center can effectively reduce energy consumption, which meets the environmental protection requirements of the new energy industry.

Reduce waste emissions: Through precise processing and efficient material utilization, waste generation is reduced, which meets the goal of sustainable development.

7. Customization and modularization

Customized production: Quickly customize charging pile shells of different specifications and functions according to customer needs.

Modular design: Support modular production to facilitate the maintenance and upgrade of charging piles.

8. Integration with other systems

Supply chain management: Integration with supply chain management systems to achieve efficient management of raw materials and finished products.

Production process optimization: Integration with other production equipment and systems (such as cutting, welding, spraying, etc.) to optimize the entire production process.

Summary

The application of intelligent flexible bending centers in the new energy charging pile industry has significantly improved production efficiency, reduced costs, improved product quality, and met the growing market demand and environmental protection requirements. These characteristics make it an important tool and competitive advantage in the field of charging pile manufacturing.