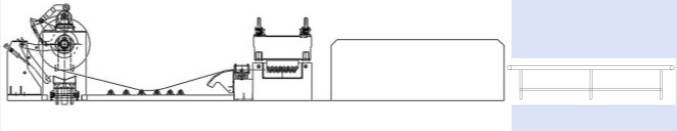

Een produksielyn wat sonder moeite deur verskeie materialen kan sny met presisie en spoed, terwyl dit elke keer konsekwente kwaliteit verseker. STON LZ1401 bied ongekende doeltreffendheid en produktiwiteit, wat dit die uiteindelike oplossing vir jou vervaardigingsbehoeftes maak. Waarom Kies STON LZ1401?

Onovertrefbare Kwaliteit: Ons laser-snytegnologie verseker presiese en konsekwente resultate, wat herwerk elimineer en materiaalverskoning verminder.

Koste-effektief: Deur produksietyd te optimaliseer en materiaalverskoning te verminder, help die STON LZ1401 jou operasionele koste te bespaar.

Toekomsbewys: Soos tegnologie voortgaan om te ontwikkel, is die STON LZ1401 ontwerp om aan te pas en saam met jou besigheid te groei.

Uitrustingparameters

|

|

rAU MATERIALEN |

Kougerolde plaat, galvaniseerde plaat, roestvrystaal |

|

2 |

plaatdikte |

0.5mm ~ 2.0mm |

|

3 |

plaatwydte |

1000mm~1500mm |

|

4 |

Gewig per rol |

≤10T |

|

5 |

Binnendiameter van die rol |

ø508mm-Ø630mm |

|

6 |

buitediameter van die rol |

ø1000 ~ Ø1600mm |

Eindprodukt parameters

|

1 |

oppervlakkwaliteit |

Die oppervlak van die band is vlak en voeg nie enige verwerkingstekortkominge by nie; |

|

2 |

Vlakmaking noukeurigheid |

±1mm\/m² |

|

3 |

Diagonale akkuraatheid |

≤1mm⁄2000mm |

Eenhede parameters

|

1 |

Gordelstryd |

5m⁄min |

|

2 |

Lynsnelheid van die eenheid |

Regstrekmasjien lynsnelheid 0~12m⁄min (aanpasbaar) |

|

3 |

Bewegingshoogte |

+800mm |

|

6 |

bewegingsrigting |

(Onderhewig aan finale werfprosesuitsetting) |

Werkomstandighede vir toerustinggebruik

|

1 |

Kragtoestande |

3φwisselstroom, 400V±5%, 50Hz±2% |

|

2 |

Lugbron (gedrukte lug) |

Druk: 0.5~0.6MPa Verplasing: 0.6m3/min |

|

3 |

waterbron |

Geen spesiale vereistes |

Toerusting verf

|

1 |

Hoofraam verfkleur |

standaardtoerusting |

|

2 |

Mobiele, veiligheids- en ander komponente |

Konfigurasie volgens primêre kleur (geel/oranje) |

|

3 |

Elektriese kasties, bedieningskonsoles, brandstoftank |

standaardtoerusting |

Toerusting Hoofkonfigurasie

|

NE. |

Kategorie |

Naam |

Oorsprong en Merk |

Hoeveelheid |

|

1 |

laser |

vesel laser |

Shenzhen Chuangxin 6000W |

1 |

|

2 |

laser Hoof |

veselaser snykop |

Shanghai Jiaqiang |

1 |

|

3 |

Koelstelsel |

waterkoeler |

Wuhan Hanli |

1 |

|

4

|

CNC-stelsel

|

Beweging Beheer Sisteem |

Shanghai Weihong |

1 |

|

Servo Bewegingstelsel |

Shenzhen Weichuang |

4 |

||

|

Reduktiereg |

Japan Beto |

3 |

||

|

Elektriese komponente |

Schneider, Frankryk |

1 |

||

|

Pneumatiese komponente |

Anwuochi, Duitsland/Yadek, Taiwan |

1 |

||

|

5

|

Masjienliggaam

|

Bedieningstafel |

Uithangende tipe |

1 |

|

Gidsrail |

Taiwan Heqing |

1 |

||

|

Glijder |

Taiwan Heqing |

10 |

||

|

Rack en pinion |

Taiwan Kotai |

1 |

||

|

Bed |

Welsing en ouderdomsbehandeling van vierkantige buis |

1 |

||

|

Rookafvoer |

Rookleiding |

1 |

||

|

6

|

Bykomende fasiliteite

|

Materiaalrek |

10T hidrauliese materiaalrek |

1 |

|

Vlakmaakmasjien |

15-wal presisievvlakmaakmasjien |

1 |

||

|

Spoegmasjien |

Roolerspoegtafel \/ bandplaatspoegplatform |

1 |

||

|

Lug kompressor |

1.6Mpa lugkompressor gespesialiseer vir laser |

1 |

Werksomgewingsvereistes

|

Item |

Naam |

Vereistes |

Aantekeninge |

|

Kragtoevoer

|

Totale geïnstalleerde kapasiteit Spanning |

≤50KVA 380V\/220V±5% |

aanbeveel om 'n 100kva-kapasiteitskrigspanningsbron te gebruik. Ander areas moet outomatiese spannings- en stroomstabiliseerders geïnstalleer word. |

|

Aardingweerstand |

≤4 ohm |

||

|

Daar moet geen sterk elektromagnetiese seininterferensie naby die installasieapparaat wees nie. Vermy radio-uitzendstations of -opdragstasies rondom die installasieplek. |

|||

|

Water |

Waterkoelerwater |

moet gezuiverde, deioniseerde of destilleerde watergasse gebruik |

|

|

gas |

Sauerstof, Stikstof |

Reinheid > 99.5% |

Parameters wissel volgens materiaalverwerking |

|

Lug kompressor |

Druk ≥1.6mpa |

||

|

Werksomgewing

|

Temperatuur |

5-40 grade |

|

|

Humiditeit |

≤80%, geen kondensering |

||

|

Grondslag |

Amplitude <50um, amplitudeversnelling <0.05g; geen groot stampende vibrasieapparatuur in die buurt. |

As die bron van vibrasie teen vibration-trench-maatregels behoort te word genome |

|

|

Ruimtevereistes vir toerusting om te verseker dat daar geen rook en stof is, om metaalpolering en snywerk en ander stoffige werksomgewings te vermy, en dit moet anti-statis vloerbedekking geïnstalleer word, met skermsdraad aangesluit |

|||

Voerwag

1.Tegniese parameters:

Draagvermoë: 20T

Verplaasingsspoed: 5-7 m/min

Horisontale beweging: hidrauliese motor

2.Die wag word bedryf deur 'n handgehoue draadlose bedieningskassie, die volume word vanaf die materiaalvoorbereidingstafel opgetel en na die posisie van die as van die rol van die ontrolaar beweeg, en die binnegat van die materiaalvolume word in die rol van die ontrolaar gesteek, waarna die wag agterwaarts afdaal en terugkeer na die oorspronklike posisie.

3.Die bo-reelwag bestaan hoofsaaklik uit 'n V-vormige saalplank, liggaam en vier-gidskolom optogingsmekanisme.

4.Die wagliggaam is 'n gesoude strukturele komponent, vierwiel-struktuur, die wagliggaam word deur die motor aangedryf, sodat die wag op die spoor beweeg.

5. Die optelmechanisme bestaan uit 'n optelkomponeer, leiingsmekanisme en 'n optelhidrauliese silinder. Die optelkomponeer maak gebruik van 'n struktuur met vier leiingskolommes, wat vloeiend optel en daal.

6. Die boonste vlak van die laaiwagie is 'n ondersteuningsplatform wat bestaan uit 'n V-vormige sadelbak. Wanneer die wagie werk, lyf die hidrauliese silinder die karretjie om die volume op of af te hef, en die motor dryf die riete van die wagie om te roteer, sodat die wagie voor- of agteruit beweeg op die spoor. Tydens bedryf word die V-vormige bak bo-op die wagie deur die hidrauliese silinder gehys om die rolle op te takel en hulle tot die benodigde hoogte te hef, en dan dryf die motorbestuurde meganisme die laaiwagie langs die radiale rigting van die aluminiumrolle op die spoor en stoot die plaatrolle teen die middelpunt van die ondersteuningsilinder van die ontrolaar aan, waarna die rolle strak teen die as van die bewegende ontrolaar word getakel.

7. Die kabel en oliebuis van die laaiwag is deur die ondersteuningsketting beskerm.

8. Oliebuise en kabele word deur sleepkettings beskerm.

Hidrauliese Outhangende Ontrolaar

1.Tegniese parameters:

Tipe: outhangende tipe, met sydige hidrauliese bykomende ondersteuning, hidrauliese op- en neergang.

Draagvermoë: ≤10T

As spanningstreek 50mm

Uitbreiding en vastsit deur hidrauliese aandrywing skeef

Aandrywing \/ mag AC7.5kw

Rem Pneumatiese skootrem

2.Funksie: Ontrolaar word gebruik om die bandspoel oop te maak en gesynchroniseerde oorblywende materiaal met die vlakker te stel.

3. Liggaam en basis:

Die masjieliggaam en basis is 'n gesoude struktuur met warmouderdombehandeling.

4. Mandrel:

Die mandrel se op- en afbeweging word bereik deur 'n hidrauliese silinder wat die uitbreidingshuls dryf.

Die ontrolmandrel bestaan uit drie uitbreidingshulpe.

Asmateriaal: 40Cr, temperingsbehandeling.

Rol: vier waaier-vormige plaatkomposisie, waaierplaat konkav-konveks verskuifde tipe, sodat dit nie in die binnevlak van die plaat 'n merkie sal maak nie. Die stijgende en inkrimpende silinderdrywing word hidraulisies aangedryf, en die rol het een gebogen plaat met 'n skaal.

5. Kragoorgang:

Tydens die proses van outomatiese bedryf word die band aktief deur die ontrolaar afgeskiet, en die motor, deur die beheersisteem, bring 'n buffervoorraad voort.

6. Tussen die proses van ontrol, word die parameters van die motor (spoed, koppel ens.) beheer volgens die parameters van die gerolde materiaal.

7. Hoofmotor en hoofdrijwiel: die motor het die volgende funksies tydens die ontrolproses:

Gesynchroniseerde oorblywende materiaal.

bladsy-invoer.

Lugmatige rem by die motor om die masjien te rem in geval van stilstand of 'n 'noodstop'.

Ontrolaandrywing: motor verminderingsaandrywing na die versnellingskakelaar, versnellingskakelaar tandwiel aandrywing spanning asp aandrywing.

Rol hulpsteun

Om die kern te voorkom dat dit inklink, is daar 'n hidrauliese hulpsteunstelsel, wat deur 'n olinder aangedryf word.

Die ondersteuningarm word deur die olinder op- en afgehef, en is in 'n selfslottoestand nadat dit verhoog is;

Lugmatige stelsel: dit bestaan uit silinders, kleppe en buise, en die koper verskaf sy eie gasbron.

Skramweerstandsendraaiertourol (saamgestel uit onderliggende rolle)

Sydewys gids sentreringstoestel

1.Gebruik: Die toestel word gebruik vir sydewys gids sentrering en afwykingskorreksie van staalstrook.

2. Tegniese parameters

Maksimum opening breedte 1650mm

Minimum opening breedte 1000mm

Materiaal van leirol GCr15, HRC60-62

3.Struktuur: roltype, met gidskolom skroefstruktuur en handwiel aanpassing.

4. Die rol word op die skyder geplaas, wat deur die handwiel bedryf word om in die gidskolom op die raam te beweeg. Die breedte van die plaat kan aan die linkerkant en regs kant individueel aangepas word.

5. 'n Horisontale drukrol word op die voeringskant geplaas om te voorkom dat die staalband uit die gidsbereik van die vertikale rol spring.

Vier-gewigstipe fynregstelmachine

1.Toerustingparameters

Aantal kniprolle 2

Aantal vlakrolle 13

Aantal ondersteuningsrolle 3 ryte bo en onder

Diameter van vlakrolle φ100mm×1700mm

Materiaal van vlakrol 40Cr, hardheid ≥HRC58-62 (temperen, kweken)

Ondersteuningsrolmateriaal 40Cr, hardheid ≥ HB250-275 (temperen, kweken, chroomplating)

Hoofmotorvermoeiing 30kw (servomotor)

Hoofvermindering harde tandwielvermindering

2. Vorm: vier-gewigstipe

3. Vingerrader bedek met rubber, bose rol cilinder gedruk af.

4. Vlakrol: die vlakrol is die hoof werkende deel van die masjien, die materiaal van die vlakrol is 40Cr, die bewerkingsproses verloop as volg: uitskakeling - grof bewerk - temperen - semi-eindbewerking - harden - fyn skuur, die oppervlaktehardheid bereik HRC58 en die oppervlakteafwerking is Ra0.8mm. Die draaias van die werksrolle gebruik self-uitrekkende draaias of naalddraaias, wat 'n groot draaikrag het, min wrywing en 'n lange dienslewe. Die bose en onderste ry van werksrolle is uitgerus met 'n aandryfstelsel, sodat die bose en onderste ry van werksrolle aktief roteer; die bose ry van werksrolle kan deur die motor aangedryf word om vertikaal op te ry, en kan ook aan die invoer- en afvoerende gereguleer word, sodat die vlakrolle skuinshang (d.w.s., die bose en onderste rolle vorm 'n harmoniese dempende regstelling om die kwaliteit van die vlakmaking van die plaat te verbeter).

5. Steunrolle: Om die vlakkeurigheid en startheid van die vlakrolle te verseker, is daar steunrolle bo en onder, waarvan die materiaal 40Cr is, en die rolaspe draai op naaldaspe. Die steunrol maak gebruik van 'n skuinsyswerkingsmekanisme wat in die vertikale rigting aangepas kan word. Die steunrolle word handmatig aangepas.

6. Kragsysteem: die hooftransmissiestelsel word deur 'n motor sentraal aangedryf, en die motorkwasspander van die oproldransmissiestelsel maak gebruik van 'n integrale struktuur met 'n kompakte en skoon voorkoms.

Hidrauliese en pneumatiese stelsel

1.Samestelling:

Hidrauliese statie en hidrauliese buisery.

pneumatiesestelsel.

2.Prestasieopsomming:

maak gebruik van die integrale pompskasie om hidrauliese krag aan elke silinder te verskaf, en is uitgerus met ooreenstemmende veiligheidskleppes, drukmetertjies, regelaars, eenrigtingkleppes, elektromagnetiese kleppes en so meer.

3.die werkskraam:

Die gebruik van hoë-kwaliteit staalplaat en -buise in die gesoude raamstruktuur, sekondêre ouwerwordingsbehandeling, presisiebewerk deur 'n groot draaibank, hierdie ontwerp- en bewerkingsmetodes verseker dat die werktuig uitstekende skokweerstand, hoë startheid en stabiliteit het. Die werktafel maak gebruik van

Boontype digte werktafel, roterende platformontwerp, kan tydens verwerking gereed wees vir die volgende laai, wat beduidend die werkeffektiwiteit verbeter.

4.stofverwyderingstelsel: Die werktafel maak gebruik van sentrale stofabsorpsieontwerp, uitgerus met stofabsorpsie-leidings, om stof, afvoergasse en ander stowwe tydens die produksieproses te verwyder.

5.Transmissiestelsel: Dit maak gebruik van hoë-presisie gesleep rek-en-tandwiel presisie transmissie en servo-stuurstelsel om die vloei en presisie van die werktuig in sy hoogsnelheidsbewegingsstaat te verseker.

6.CNC-stuurstelsel.

Die CNC-snykontrooprogram is gebaseer op die Windows-stelselontwikkeling, en die CNC-kontrolesisteem kan die volledige koppeling van laser-sny-professionele CNC-softeware realiseer, deur 'n professionele PC-industriele beheermasjienbedrywing te gebruik, grafiese koppelvlak, maklik om te bedryf, vriendelike koppelvlak, maklik om te leer, vinnige bedrywing, die CNC-program is maklik om te redigeer, leesbaar. AutoCAD, CorelDraw en ander professionele sketsprogramme, uitgerus met 'n snyprosesparameters databasis, snyparameters kan tydens die snyproses in reële tyd aangepas word om die beste snykwaliteit te bereik.

7. nesting-software:

(1) spesifiek vir die ontwikkeling van CNC-snymasjiene, tekenprogrammerings-nesting-software vir gebruik op die rekenaar. Die hooffunksies sluit in CAD-tekeninge, die nuwe weergawe van CAM-DUCT-leidingontbindingsprogram, DXF/DWG-optimering, interaktiewe nesting, outomatiese programmering, asook sny-simulasieverifikasie en kosteberekening.

(2) CAM-DUCT lugpijp sagteware sagteware kom saam met 300+ lugpijp grafiese sagteware wat 'n enkele uitleg meervoudige grafiese super plaatgrootte kan wees, grafiek kan outomaties geskei word, outomaties aanmekaar gevoeg word en 'n goeie aanhegsmond grootte laat.

(3) Nesting sagteware is die kern tegnologie van CNC-sny masjiene om voltyd sny, hoë-effektiwiteit sny en hoë nesting tarief sny te verwezenlik, wat die fundamentele waarborg is om effektief staal te spaar en sny effektiwiteit te verbeter.

Koel af

Professionele waterkoelsisteem, dual temperatuur dual beheer kan bereik word, twee waterwye koel die twee kern posisies, die temperatuur van die koelingeenheid tot die digitale tafel wys, as die water temperatuur bo die spesifiseerde temperatuur van die koelingeenheid styg sal dit outomaties die water temperatuur koel, is laer as die spesifiseerde temperatuur van die koelingeenheid sal dit outomaties stop met koel.

Masjienformaat

Die 3015 model het 'n effektiewe sny-streek van 3 meter lank * 1.5 meter wyd, die totale lengte van die masjien beslaan ongeveer 20 meter, en die wydte beslaan ongeveer 5 meter.

Diensverpligting

Voor-verkoop diens:

Volgens die ontwikkelingsbehoeftes van kliënte, vanuit die oogpunt van die werklike gebruik deur kliënte, om gepaste tegniese begeleiding en 'n volledige stel toerustinginligting te verskaf;

Los die verskillende probleme wat deur kliënte aangebring word op, vanuit oorwegings van tegniese uitvoerbaarheid, vir kliënte of om kliënte te help met die ontwerp en ontwikkeling van 'n laser-verwerkingprogram;

Verskaf toerustingstelling sodat kliënte die inspeksie, monsters, toetsmasjiene en so meer kan besoek.

Tussen-verkoop diens:

Die werklike gebruik van die kliënt se masjienerigging plaasinspeksie en -analise, volgens die kliënt se plek om gebruikers te help met die beplanning en ontwerp van die plek sowel as water-, elektriese- en gasrangskikking vir die toerusting en so meer;

Verskaf kliënte 'n volledige stel toerustingbedryfshandleidinge en verskaf opleiding aan die toerustingoperateurs van kliënte;

Naverkoopdiens:

By die gebruik van die plaas deur die gebruiker, word die toerustingoperateurs van die kliënt vir die werklike bedryf van die prosessering, daaglikse onderhoud van die toerusting en veilige gebruik van die beskerming opleiding verskaf om te verseker dat die gebruiker so gou moontlik die toerustingbedryfprosedures en -metodes kan beheers en onafhanklik die toerusting kan gebruik vir produksie en verwerking;

Die hele stel toerusting ná installasie en kommissioneerings by die gebruiker, sedert die datum van opleiding in die masjien een jaar garantieperiode, die laser twee jaar garantieperiode;

Tans die garantieperiode, sal die maatskappy ook kundige diensverskaffers aanwys om van tyd tot tyd tegniese patrouilles by die werf van die gebruiker se toerusting uit te voer, van tyd tot tyd regstellende onderhoud en inspeksies van die toerusting te doen en vrae wat deur die gebruiker gestel word, te beantwoord.

Ander sake

1、Projekvoortgang

Siklus tyd van ongeveer 45-60 werksdae, volgens die kontrak siklus om die ontwerp, vervaardiging en aanvaarding van die werk te voltooi en na die vraekant te stuur;

2、Installasie en kommissioneerings

Toerusting gestuur na die vraekant, 7-10 dae installasie- en kommissioneeringsiklus;