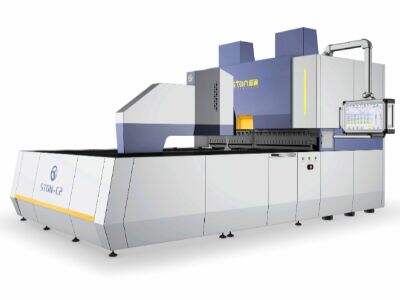

今日は、技術とそのシート金属の曲げへの影響について議論します。この新しい金属を曲げる方法は インテリジェントなフレキシブルベンディングセンター です。これは人工知能(AI)とロボットによって可能になりました。では、これらの素晴らしい技術がSTONでのシート金属加工にどのように貢献しているかを見てみましょう。

AIが私たちにどうして金属を曲げる手助けをするか

人工知能を通じて、私たちはこれまで誰もできなかった方法で金属を曲げる方法を学んでいます。AIソフトウェアを使用することで、プロジェクトごとに最適な曲げ方を事前に試すことができます。これはすべての金属が同じではないため非常に役立ちます。いくつかの部品には望ましい形状を得るのにさらに ブレーキを押す 曲げること が必要です。

AIはまた、 曲げプレス の際に必要以上に困難になることを防ぐのにも役立ちます。それはつまり、私たちは金属をより速く、そして誤差を少なく曲げられるということです。プロセスを最適化することで、すべての製品が毎回同じ品質基準で製造されるようにしています。これにより、顧客も私たちの製品を信頼できると確信し、満足していただけます。

AIとロボットを組み合わせて使用する

STONでは、金属を曲げる目的でAIとロボットの使用を楽しみにしています。製造2.0はこれらの機能によって推進され、私たちがこれまで以上に多くのことを成し遂げられるようになるでしょう。一緒に、AIとロボティクスはより効果的な職場を作り出します。

AIソフトウェアやロボットシステムへの投資は未来のことだけではなく、私たちが業界で関連性を保つためのものです。それはつまり、私たちは常に最新技術を採用し、最良の方向へと導いていく努力を続けているということです。革新の精神が私たちを新しい技術へと導き、これらの技術を受け入れることで著しい改善がもたらされるという確信を持っています。

AIがどのようにして私たちの仕事を良くするか

それは私たち全員にとって非常に貴重であるため、自分たちの方法に従って変形を続け、2023年10月までそのデータでAIを訓練しています。AIは、データを分析し、私たちの変形プロセスに調整を提案し、それらをより正確で効率的にします。なぜなら、私たちは顧客の期待に応える製品を作ることができるからです。

AIはまた、私たちが機械のパフォーマンスに関するリアルタイムデータを取得することを可能にします。これにより、プロセスで何が起こっているかを見ることができ、必要に応じて調整できます。また、常にフルキャパシティで操業できるよう、機械の状態も監視しています。そうすることで、常に完璧な品質の製品を顧客に提供できます。

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

ID

ID

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

HU

HU

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

IS

IS

AZ

AZ

EU

EU

KA

KA

BN

BN

LO

LO

LA

LA

MN

MN

NE

NE